| |

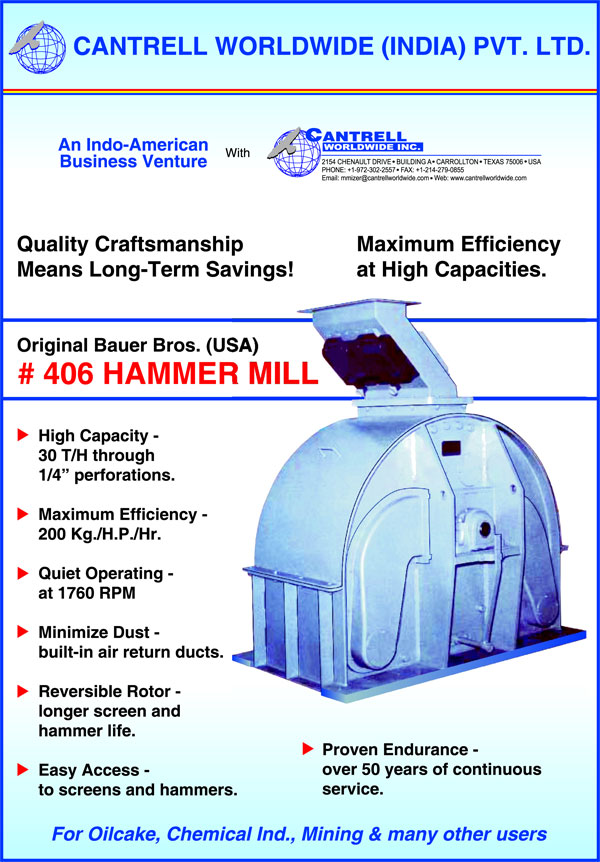

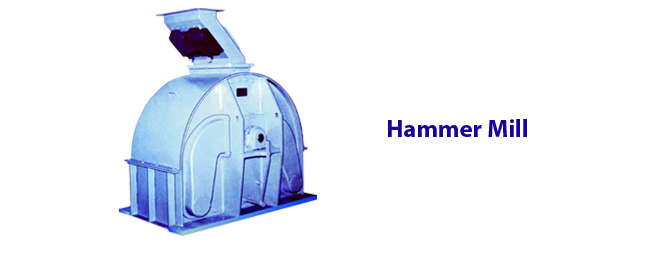

No. 406 Hammer Mill has extra high capacity rated at 200 Kg. / H.P. / Hr. With 1/4" perforated screens. At 1760 RPM and very low noise levels, the 150 H. P. Motor grinds up to 30 TPH of solvent extracted soybean cake or similar vegetable oil seed residues.

Rotor of me NO. 4Ub may be rotated in either direction which prolongs both hammer and screen life and greatly reduces downtime.

The central top feed equally distributes the load over the full width of the rotor and allows high efficiency in both direction, enhancing uniform wear of hammers and screens, and permits using one style hammer throughout. These design features afford a granular grind with minimum fines.

|

|

| |

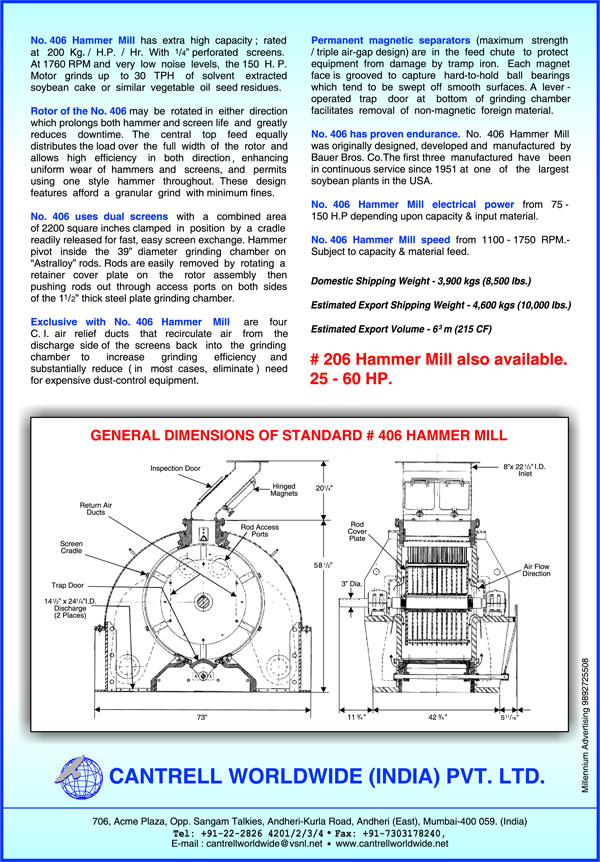

No. 406 uses dual screens with a combined area of 2200 square inches clamped in position by a cradle readily released for fast, easy screen exchange. Hammer pivot inside the 39" diameter grinding chamber on "Astralloy" rods. Rods are easily removed by rotating a retainer cover plate on the rotor assembly then pushing rods out through access ports on both sides of the 11/2" thick steel plate grinding chamber.

Exclusive with No. 406 Hammer Mill are four C. I. air relief ducts that recalculate air from the discharge side of the screens back into the grinding chamber to increase grinding efficiency and substantially reduce ( in most cases, eliminate ) need for expensive dust-control equipment.

Permanent magnetic separators (maximum strength / triple air-gap design) are in the feed chute to protect equipment from damage by tramp iron. Each magnet face is grooved to capture hard-to-hold ball bearings which tend to be swept off smooth surfaces. A lever -operated trap door at bottom of grinding chamber facilitates removal of non-magnetic foreign material.

No. 406 has proven endurance. No. 406 Hammer Mill was originally designed, developed and manufactured by Bauer Bros. Co. The first three manufactured have been in continuous service since 1951 at one of the largest soybean plants in the USA.

No. 406 Hammer Mill electrical power from 75 -150 H.P depending upon capacity & input material.

No. 406 Hammer Mill speed from 1100 - 1750 RPM.-Subject to capacity & material feed. |

| |

- Suitable for Grinding of Seed, Grinding DOC, Grinding Sunflower Seed Hulls, Grinding Feed Meal

- High Capacity - 30 T/H through 1/4" perforations.

- Maximum Efficiency - 200 Kg./H.P./Hr.

- Quiet Operating - at 1760 RPM

- Minimize Dust - built-in-air return ducts

- Reversible Rotor - longer screen and hammer life

- Easy Access - to screens and hammers.

- Proven Endurance - over 50 years of continuous service.

- The pre cleaned seed from conveyor carried to CSP plant & sand separted can be collected below dust conveyor.

|

Home

Home